SACEME intensive mixer applied perfect structure and advanced mixing technology for the production of various kinds of regular and special ref ractor material.

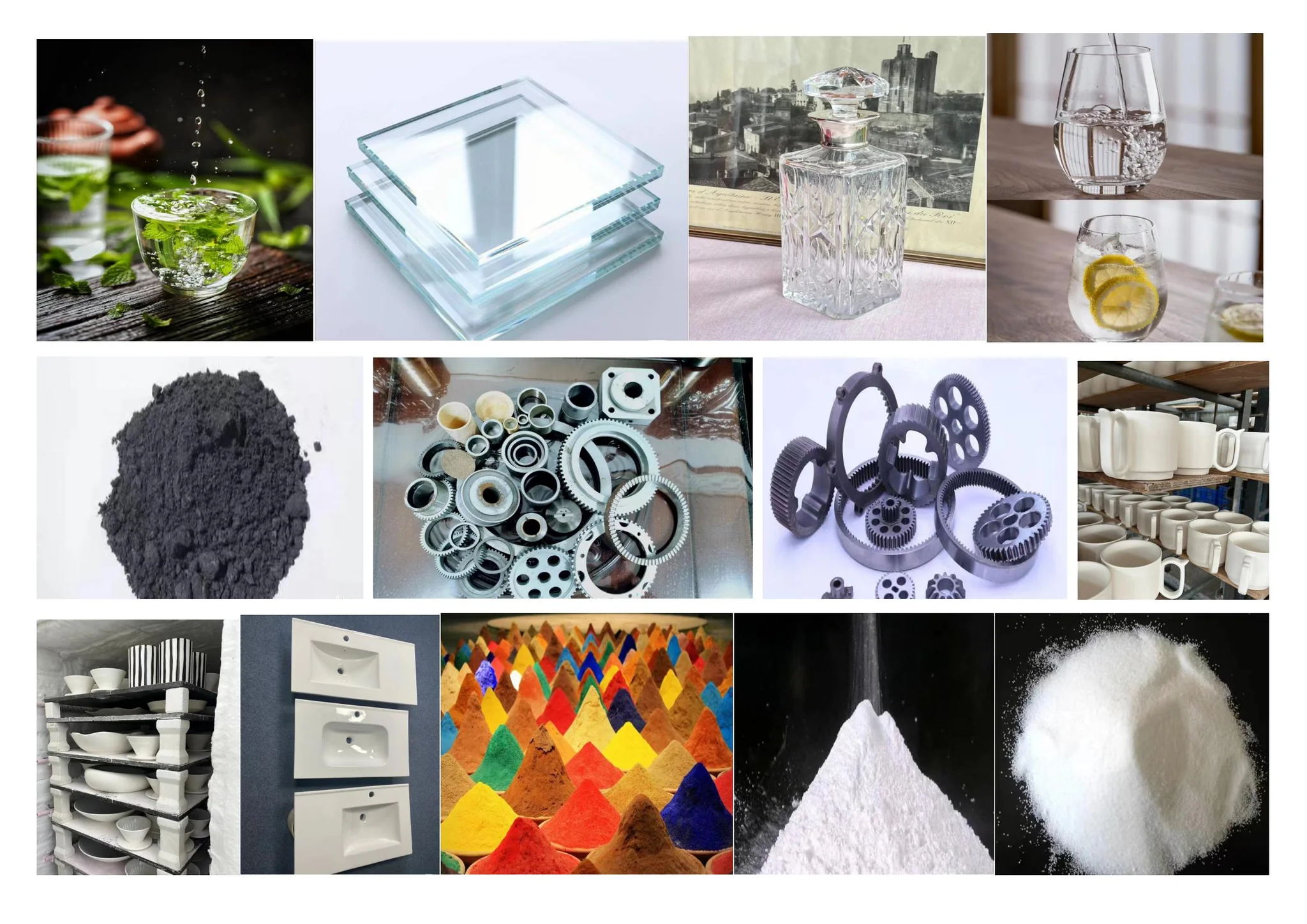

Molding materials, molecular sieves, proppants, dental materials, ceramic tools, abrasive materials, oxide ceramics, grinding balls, ferrite, etc.

building materials

Brick, expanded clay, perlite and other media, refractory ceramsite, clay ceramsite, ceramsite filter material, ceramsite brick, ceramsite concrete, etc.

Glass powder, carbon, leaded glass powder, waste glass slag, etc.

Zinc lead ore, ore, silicon carbide, iron ore, etc.

Slaked lime, dolomite, phosphate fertilizers, peat fertilizers, mineral materials, chemical fertilizers, phosphate fertilizers, carbon black, etc.

Filter powder, fly ash, cement powder, fly ash, lead oxide, coal ash, slag, powder.

Carbon black, metal powder, zirconia, etc.

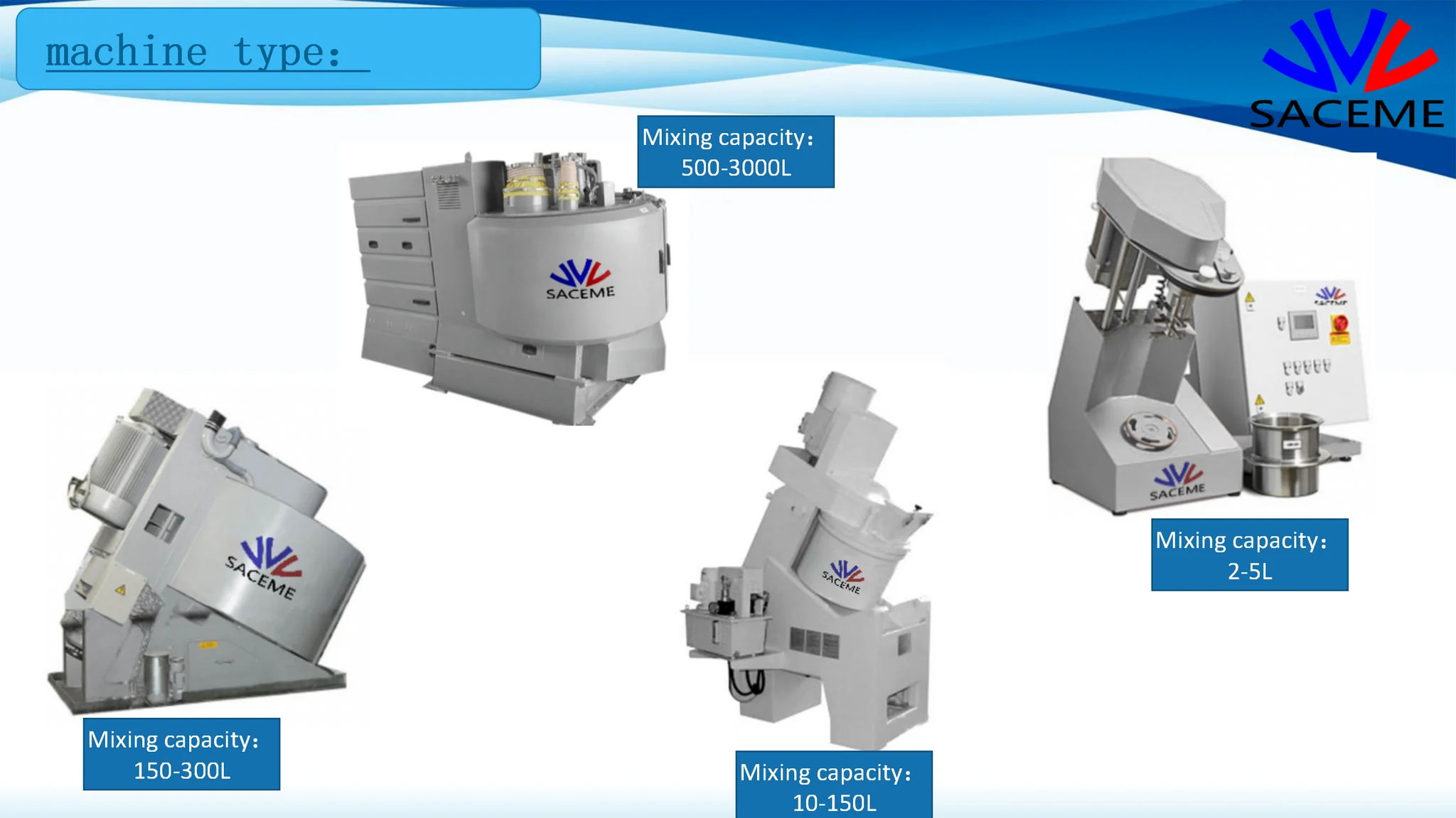

Following pictures shows the mixing volume loading capacity of one batch of processing capacity. The average mixing time is within 1 -5minute and the granulation time is within 3-5 minutes

Email: sacememachine@gmail.com

Whatsapp: 8613589250900

Phone: +86187-6628-6738